PrintCity On The Road – TCT3Sixty 2025

TCT 3Sixty is the UK’s premier event dedicated to 3D printing and additive manufacturing (AM), held annually at the NEC in Birmingham. Organized by the TCT Group, this exhibition serves as a comprehensive platform showcasing the latest advancements in AM technologies, including cutting-edge machines, materials, software, and services.

Beyond the exhibition floor, TCT 3Sixty offers a robust conference program featuring presentations from industry leaders, case studies, and panel discussions that delve into the practical applications and future of AM technologies. The event attracts a diverse audience, including designers, students, engineers, and decision-makers from sectors such as aerospace, automotive, healthcare, and consumer products, all seeking to explore and adopt innovative manufacturing solutions . With its comprehensive approach, TCT 3Sixty continues to be a pivotal event for professionals aiming to stay at the forefront of additive manufacturing advancements.

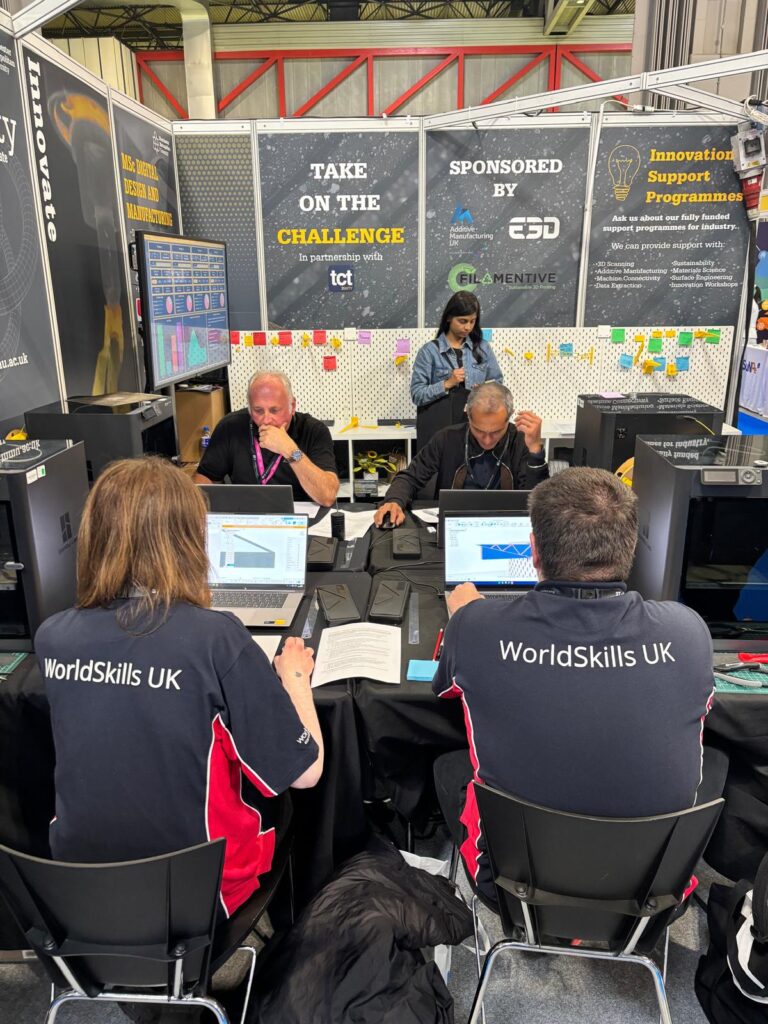

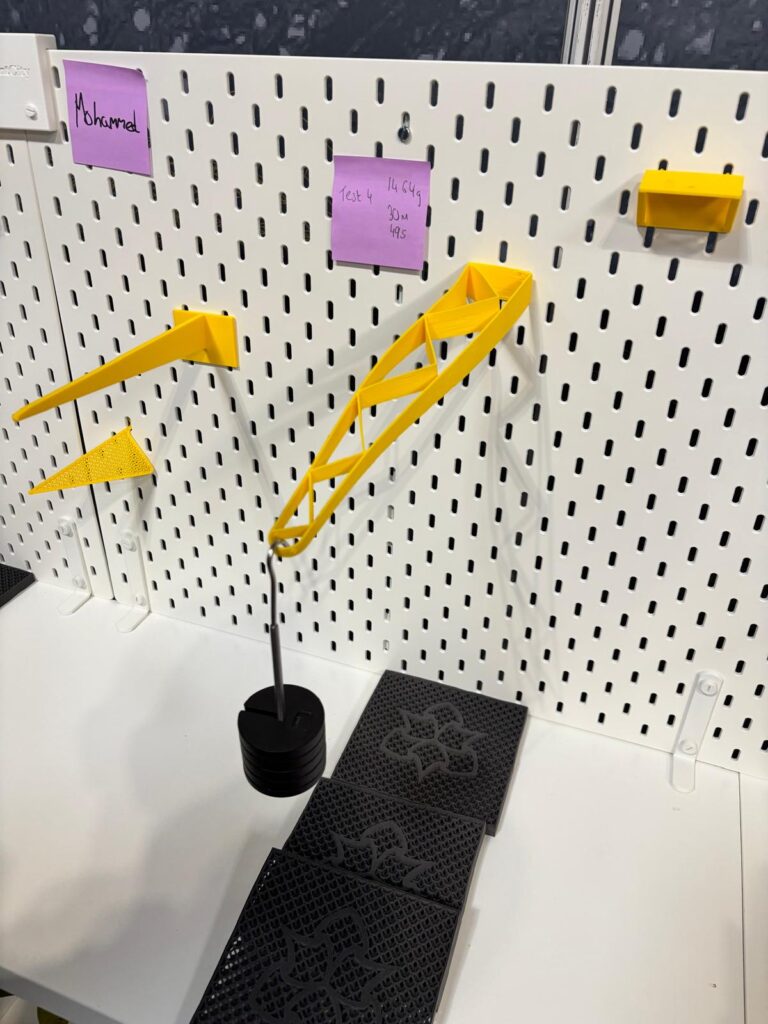

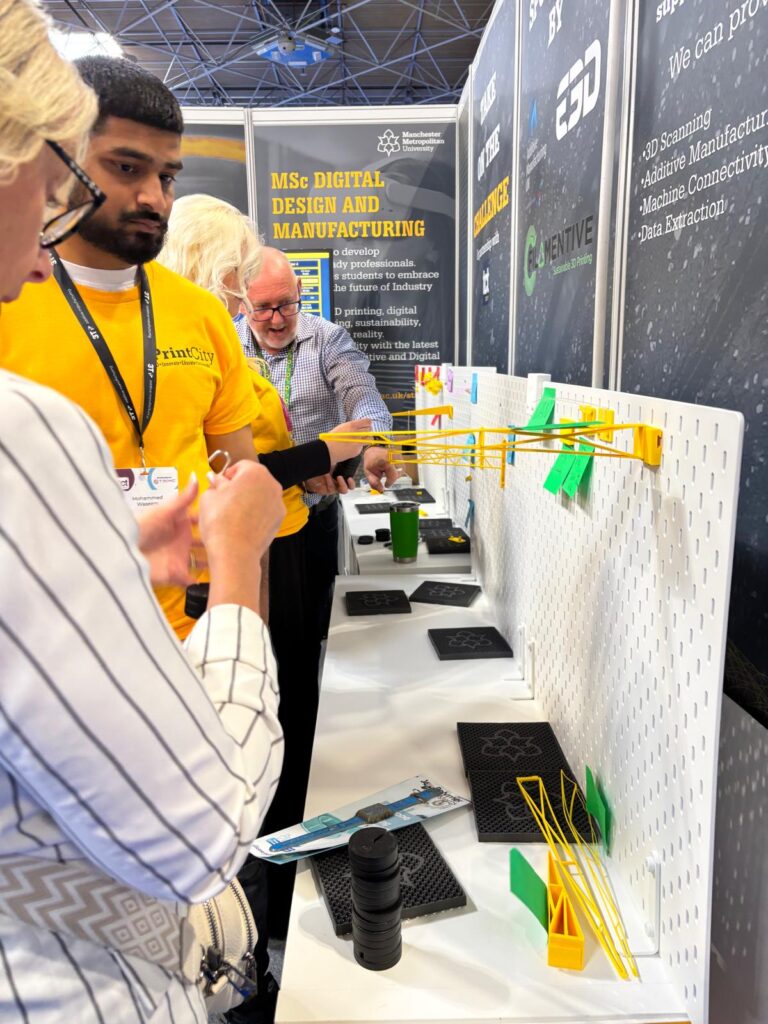

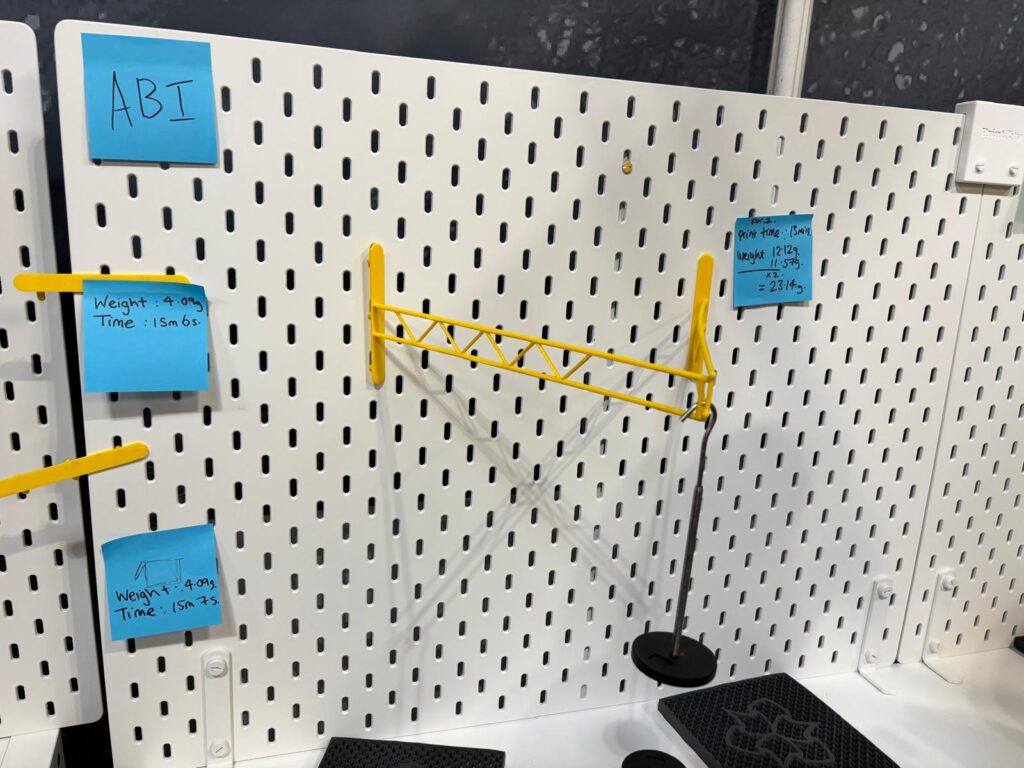

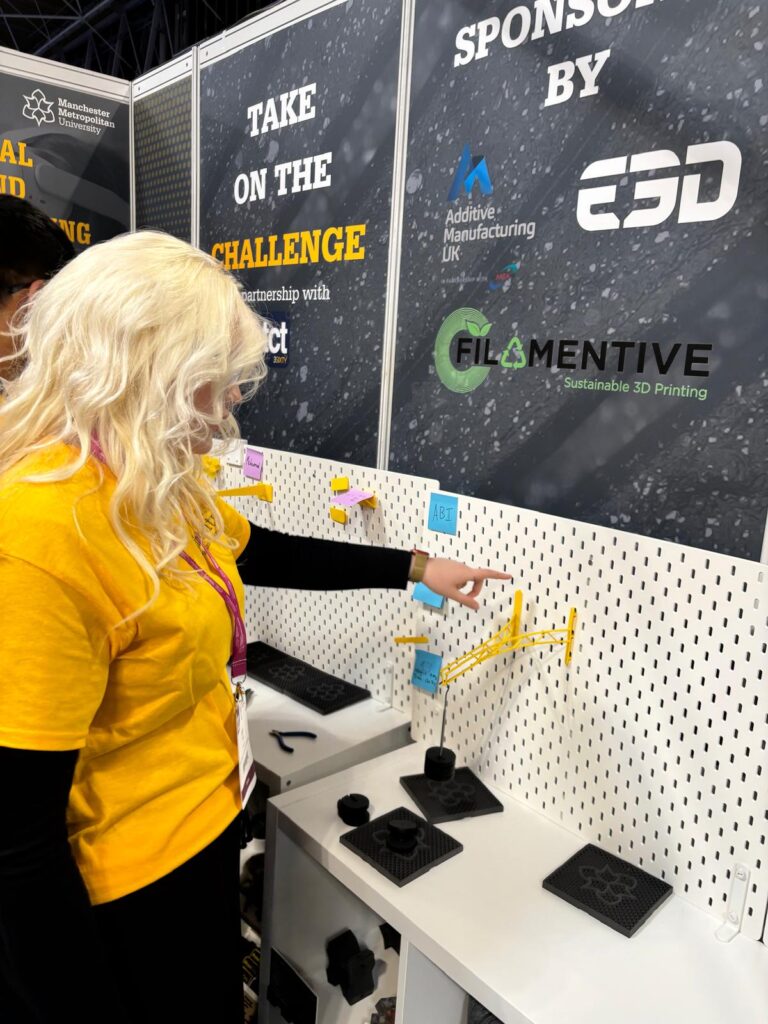

In our third year at ‘TCT’, we decided to change things around a bit and do something completely new that focussed on our MSc course and it’s wonderful crop of students. Rather than fill our stand with example 3D prints, we set up to run a ‘design and make’ challenge where we pitched 4 students head-to-head against the clock to create a 3D printed bracket to retain a set of weights. On day two, we opened the competition to everyone.

The competition was sponsored by AMUK, E3D and Filamentive and we thank them for their support.

With an Ender-3 V3 SE printer as a prize on each day, competition was fierce to make the best part to a set of criteria.

The competition guidance given follows …

Your challenge is to rapidly prototype 3D printed designs to hold as much weight as possible at the farthest distance from the pegboard, using the least material.

Conditions

- The weight must be suspended by its hook and hold at least 500g,

- You may use as many peg holes as you wish per design,

- The weight must not touch the pegboard or floor.

For each design 3D printed you should:

- Configure your preferred 3D print settings in Bambu Studio,

- Record the overall amount of material (grams) used and total printing time (prepare time and printing time) on a Post-It note,

- 3D print the design,

- Remove and weigh the part before and after post-processing/removal of any support material then record the amount of support material in grams (g) on the Post-It note,

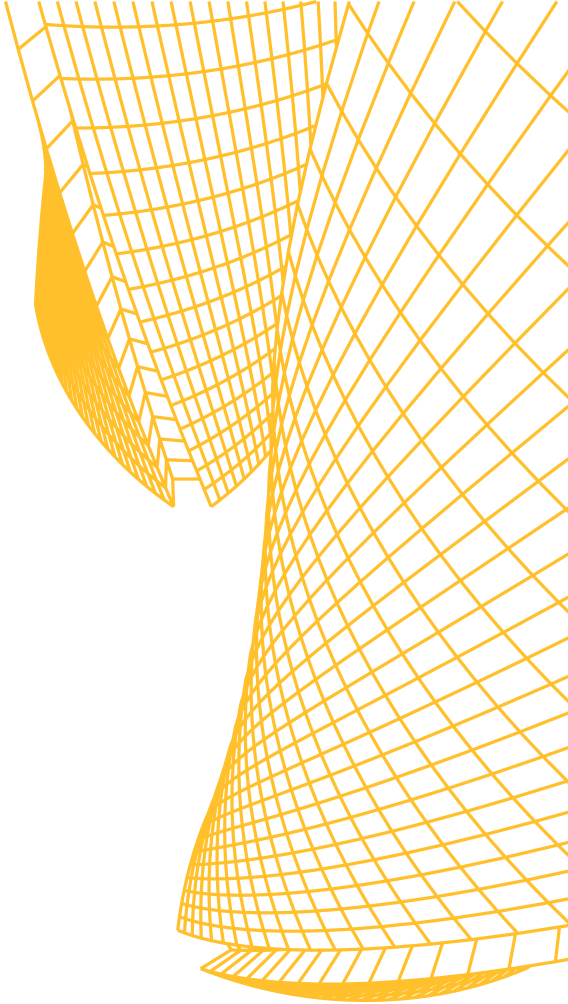

- Attach the 3D printed design to the pegboard and affix the Post-It note alongside it.

Marks will be awarded for the following:

- 20%: m: overall mass of 3D printed part (in grams, lower is better)

- 20%: tt: total print time in seconds (lower is better)

- 30%: ss: mass the part can support before failure (higher is better) (Min 500g)

- 10%: uu: support material used (in grams, less is better) (Max 10g, Min 0g)

- 20%: dd: maximum distance from peg board (in mm, higher is better)

A score will be calculated using:

- Score=100×(0.2xm+0.2xtt+0.3xss+0.1xuu+0.2xdd) and recorded as a percentage.

If you imagine a Venn diagram where each of these criteria intersect, there is an optimal sweet spot in the middle where all these criteria would be optimal and that was the goal.

Photo gallery

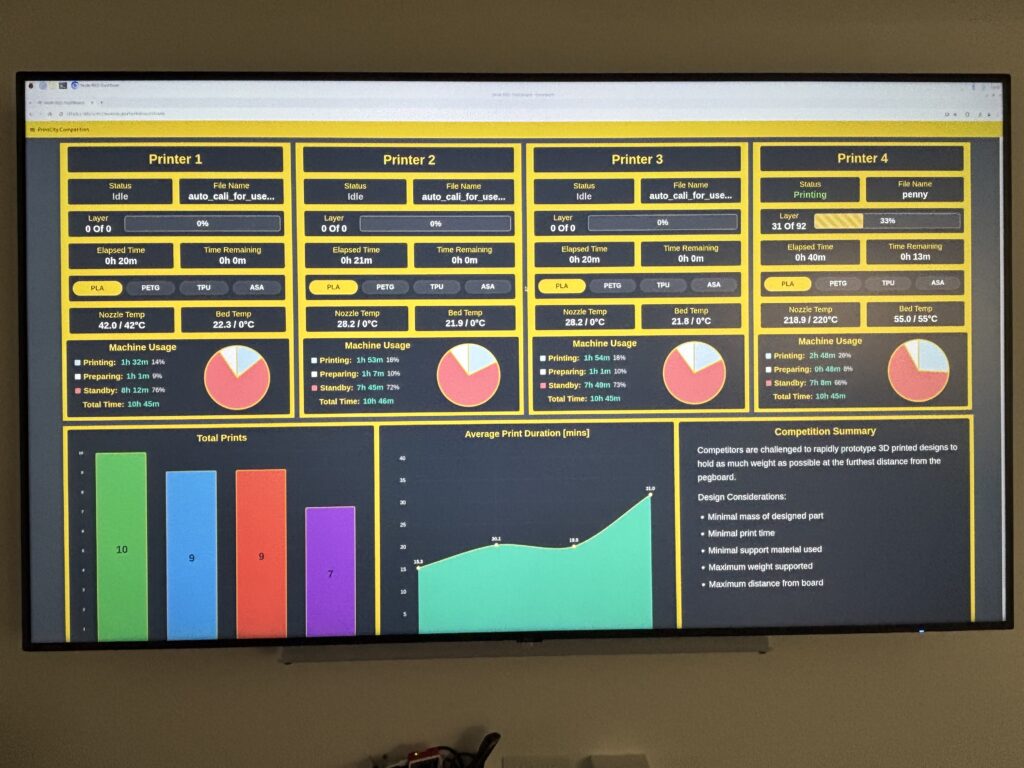

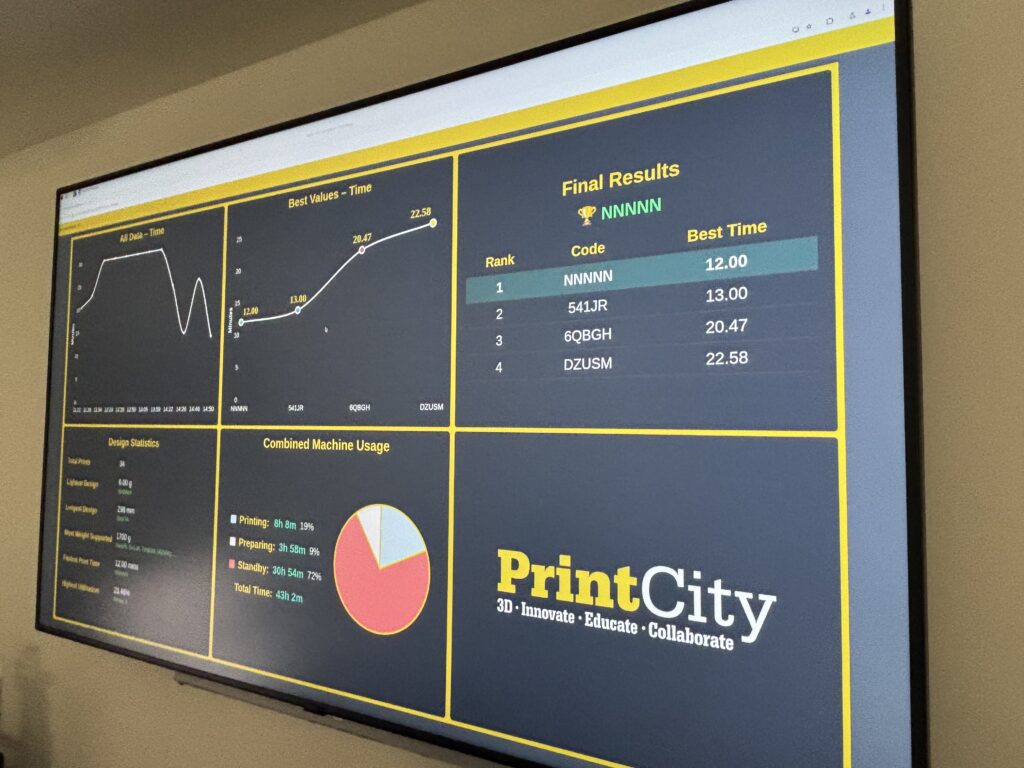

PrintCity’s very own James McKeown produced a custom-coded application to wirelessly harvest live 3D printing data from the 4 Bambu printers so visitors could see how the competition was progressing.

His system also collated all the data for each criteria to provide a stunning visual summary (pictured below) of who was leading, with each competitor represented by a unique 5-digit identifier code that only they know so if they walked past, they could see how their entry was performing against others.

The competition turned out to be a huge success and a real draw for visitors to TCT. We are hopeful to run something along similar lines in the future.

If you are interested in joining our MSc Digital Design and Manufacturing course, there are full details, including how to apply here:

Get in touch

If you're interested in working with us, or have questions about studying with us please get in contact.

Related Blog Articles